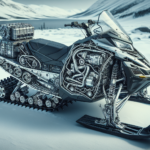

Swooshing and gliding across chilly landscapes, you might think that snowmobiles have tons of snow at their disposal to keep their engines cool. Yet, that’s not quite accurate. This article is set to unravel the intriguing process of how snowmobile engines stave off heat while delivering seamless performance. So, cozy up, you are about to journey through the chilling mechanisms of snowmobile engines — a dance of engineering prowess and ski-level coolness.

Understanding the Basics of Snowmobile Engines

Riding a snowmobile is an exhilarating experience, but have you ever stopped to consider what’s under the hood? Understanding the basics of snowmobile engines helps you maintain your machine and also solve minor issues when they arise.

The structure of a snowmobile engine

When you peek into a snowmobile’s engine, you will find a few key components. There are cylinders where combustion happens, pistons that transfer the energy generated, a crankshaft, an exhaust system, and cooling mechanisms to protect the engine from overheating. All these elements work together to move you and your sled through the snow.

The role of oil in snowmobile engines

Just like in your car, oil in your snowmobile engine performs two major functions. It lubricates the engine’s moving parts to reduce friction, and it helps cool the engine by absorbing some of the heat generated by the combustion process. Regular oil changes are essential to ensure your engine runs smoothly and stays cool.

The key components involved in engine cooling

Engine cooling is crucial for the longevity and performance of your snowmobile. There are two main types of cooling systems in snowmobiles: air-cooled and liquid-cooled. Depending on your model, your snowmobile engine employs a combination of airflow (in the case of an air-cooled engine) and engine coolant (for a liquid-cooled engine) to prevent overheating. Heat exchangers also also assist in managing engine temperatures.

Types of Snowmobile Engines

Before diving further into engine cooling systems, let’s first clarify the types of engines your snowmobile might have.

Two-stroke engines

Two-stroke engines are common in older, lighter snowmobiles. In a two-stroke engine, the compression and combustion phases happen simultaneously, making it far more lightweight and simple in construction compared to four-stroke engines. However, two-stroke engines are less efficient, produce more pollutants, and require a mix of oil and gas for lubrication.

Four-stroke engines

The modern snowmobiles are more likely to have a four-stroke engine. These engines have separate intake, compression, combustion, and exhaust strokes, making them more efficient and cleaner. They are larger and heavier than two-stroke engines and require engine oil for lubrication.

Comparing the cooling mechanisms of two-stroke and four-stroke engines

Typically, most two-stroke engines are air-cooled while the four-stroke counterparts benefit from liquid cooling systems. However, that’s a generalization and you will find exceptions. The type of cooling system employed depends more on the design of the snowmobile rather than the type of engine.

Air Cooling System in Snowmobile Engines

Particularly prevalent in older or simpler models, air cooling is a straightforward way of keeping engine temperatures in check.

How air cooling works

In an air-cooled engine, chassis design allows ambient air to flow directly across the engine, absorbing heat and cooling it down. Each cylinder usually has cooling fins to increase surface area and thus, improve heat dissipation.

Advantages of air cooling systems

Air cooling systems boast a simple, lightweight design – they don’t need a radiator, water pump or the coolant itself. Therefore, they cost less to build and maintain.

Disadvantages of air cooling systems

However, the effectiveness of air cooling is often less consistent, as it mostly depends on the external air temperature and the speed of the snowmobile. It’s also louder due to the presence of cooling fins and less efficient than liquid cooling in high-demand situations.

Liquid Cooling System in Snowmobile Engines

Gaining more popularity in modern models, liquid cooling is an extremely effective method of moderating engine temperature.

How liquid cooling works

A liquid cooling system works by circulating engine coolant through tubes in the engine block and heads. As the coolant circulates, it absorbs heat from the engine. The heated coolant then passes through the radiator where it loses heat to the surrounding air before going back into the engine.

Advantages of liquid cooling systems

Liquid cooling systems are more efficient and reliable than air cooling ones. They offer consistent performance, regardless of external temperature or speed, and can quickly adapt to changes in engine workload.

Disadvantages of liquid cooling systems

On the flip side, liquid-cooled engines are more complex and heavier. They also require more maintenance as the coolant needs to be checked and replaced regularly.

How Heat Exchangers Work in Snowmobile Engines

Heat exchangers are essential for efficient cooling of a snowmobile engine, especially if it uses liquid cooling.

The role of heat exchangers in engine cooling

A heat exchanger works by transferring heat from the hot engine coolant to the cooler surrounding air or snow. This process heats up the air or melts the snow, cooling the engine coolant in the process.

Types of heat exchangers used in snowmobiles

Snowmobiles use two types of heat exchangers, air-to-liquid and liquid-to-snow. An air-to-liquid heat exchanger looks like a radiator. The hot coolant transfers its heat to the surrounding air. A liquid-to-snow heat exchanger uses the snow’s ability to melt and absorb heat to cool the engine coolant.

How heat exchangers improve the efficiency of engine cooling

Heat exchangers are very efficient at dispersing heat. They increase the surface area in contact with the cooling medium (air or snow), speeding up the heat transfer process. Also, they are designed to maximize the time the coolant is in contact with the cooling medium to maximize cooling.

The Role of Coolant in Snowmobile Engines

For a liquid-cooled engine to function optimally, it needs a good engine coolant.

What is engine coolant

Engine coolant is a specially formulated fluid that circulates through a snowmobile’s engine to absorb heat. It’s usually a mixture of distilled water and antifreeze to ensure it remains liquid in freezing temperatures and doesn’t boil under high engine heat.

How coolant facilitates the cooling process

The coolant absorbs heat from the engine and transfers it through the heat exchanger to the cooler surrounding air or snow. This process helps protect your engine from overheating and heat-related damage.

Maintenance and replacement of coolant

Coolant doesn’t last forever. Over time, it can degrade, losing its ability to efficiently absorb and transfer heat. For this reason, regular checks and timely replacement of coolant are essential maintenance steps for a liquid-cooled snowmobile engine.

The Importance of Proper Engine Cooling in Snowmobiles

Engine cooling is not something to be overlooked or underestimated in a snowmobile.

Protecting engine components from heat damage

Your snowmobile’s engine produces a lot of heat when in operation. Without proper cooling, this heat can lead to engine component damage and a serious loss in performance or even a breakdown.

Enhancing the performance and longevity of the engine

A properly cooled engine operates more efficiently, providing better performance. Also, it experiences less thermal stress, which can extend the engine’s lifespan.

Preventing engine overheating issues

An overheated engine can lead to many problems, like piston seizure, head gasket failure, and even engine fire in extreme cases. A well-maintained cooling system ensures that such overheating issues are kept at bay.

Common Cooling-Related Problems in Snowmobile Engines

Despite the best maintenance, snowmobile engines can sometimes encounter cooling-related issues.

Overheating

Overheating is a common problem in snowmobile engines. It can be due to low coolant levels, a malfunctioning heat exchanger, poor air flow, or running the engine too hard for an extended period.

Coolant leakages

Leakages are another common issue. A leak can lead to low coolant levels, which reduces the cooling system’s ability to keep the engine cool.

Airlock in the cooling system

Sometimes, an air pocket can form in the cooling system, obstructing the flow of coolant. This phenomenon, called airlock, can cause inefficient cooling and lead to overheating.

Wear and tear of the heat exchanger

The heat exchanger, over time, can suffer from wear and tear or even damage from rocks and debris. A damaged or worn-out heat exchanger can fail to cool the engine coolant efficiently, impacting the overall cooling efficiency.

Maintenance Tips for Snowmobile Engine Cooling Systems

Regular maintenance can help keep your snowmobile’s cooling system in top shape.

Regular coolant check and replacement

Check your coolant level frequently, especially before long rides. Also, replace it as recommended by the manufacturer to ensure it is effective at absorbing and transferring heat.

Inspection and repair of heat exchangers

Inspect your heat exchangers regularly for any signs of damage or wear. If required, get them repaired or replaced promptly to maintain cooling system efficiency.

Ensuring adequate air flow for cooling

Whether you have an air-cooled or liquid-cooled engine, maintaining good airflow is critical. Make sure there’s no obstruction to the air intake or the fan.

Maintenance of the cooling system in storage and offseason

It’s not just in the snowy season that you need to care for your cooling system. Proper maintenance of the cooling system is required even in storage and during offseason to prevent any rust or damage.

Innovations in Snowmobile Engine Cooling Technology

The world of snowmobile engine cooling technology is not static. Innovation and improvements are continually being made.

Advanced heat exchangers

Advanced heat exchangers are being designed to make them more efficient, durable, and lightweight.

Improved coolant formulations

New coolant formulations are providing better heat transfer capabilities, helping to keep engines cooler.

Smart cooling systems with sensors and automated controls

Some snowmobiles are now equipped with smart cooling systems. These systems utilize sensors to monitor engine temperature and adjust the cooling system operation accordingly, promoting optimum engine performance and reliability.

In conclusion, understanding the cooling system in your snowmobile’s engine is crucial to maintaining it in good working condition. Now that you have a clear understanding of how it works and the important role it plays, you’re better equipped to recognize problems early and take appropriate measures. Maintaining a well-functioning cooling system ensures that you can enjoy your snowmobile rides without worry. Happy sledding!

- What Snowboard Bindings Should I Get? - January 23, 2024

- What Size Screws For Snowboard Bindings? - January 23, 2024

- How To Snowmobile On Water? - January 23, 2024