Imagine the thrill of smoothly maneuvering your Polaris snowmobile through the snow-capped mountain terrain. But just as you are reveling in the adventure, a mechanical hiccup threatens to halt your journey. One common issue you might face is related to the secondary clutch in your snowmobile. In this article, you’re going to learn everything about how to remove the secondary clutch on your precious Polaris snowmobile. Because when you are in the middle of nowhere with the chilling wind nipping at your face, you want to be your own savior. Be prepared to rectify the issue yourself and get back on track to continue your thrilling escapade.

Understanding the Clutch System on Polaris Snowmobiles

The Clutch System on Polaris Snowmobiles can seem like a complex mechanism. Here, we’ll unravel this intricacy and make it simpler for you.

Definition of a Clutch System

Think of the clutch system as the middleman between the engine and the transmissions. In simple terms, it’s a device that engages and disengages the power transmission. And in case you’re wondering, your Polaris Snowmobile has not one, but two clutches – the primary (or drive) clutch, and the secondary (or driven) clutch.

Role of the Secondary Clutch

While it might play second fiddle to the primary clutch, the secondary clutch is just as crucial for the smooth functioning of your snowmobile. It works in tandem with the primary clutch to transfer the engine’s power to track, helping you zip down those frosty terrains.

Operation of the Clutching System

The clutch system works on the mechanics of transmitting and varying power. When you rev up the engine, the primary clutch senses the engine RPM and feeds power via the drive belt to the secondary clutch. This action, in turn, directs the power to the track.

Preliminary Steps Before Removing the Secondary Clutch

Before you start disassembling your snowmobile, let’s cover some bases.

Checking the Owner’s Manual

Rule number one: always consult the owner’s manual. It is your ultimate guide to the unique specifications of your snowmobile setup.

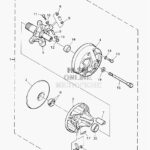

Identifying the Right Tools

Standard tools include a clutch puller, a holding bolt, and a set of wrenches. Remember, using the correct tool is critical to prevent damage to your clutch system.

Creating a Safe Workspace

Find a work area with good lighting and ventilation, and plenty of room to keep your tools handy and neatly organized. A cluttered workspace can result in lost or damaged parts.

Safety Measures to Take

Personal safety is paramount. Make sure to use safety glasses and gloves at all times to protect yourself from potential injury.

Proper Identification of the Secondary Clutch

The secondary clutch can be identified as the clutch closest to the back of the snowmobile. It’s essential to identify it correctly, as the primary and secondary clutches have different configurations and functions.

Inspecting the Secondary Clutch

If your snowmobile has been feeling a bit off lately, your secondary clutch could be the culprit.

Visual Inspection

Start your inspection by looking at the external condition of the clutch. Look for any visible damage such as cracks or broken parts.

Checking for Damages

Inspect the sheaves closely for any grooves or damage. This not only affects performance but can also cause severe damage to the drive belt.

Identifying Signs of Wear and Tear

Check for worn-out sleeves, bearing, and bushings. An increase in friction due to these worn-out parts can severely hamper the performance of the secondary clutch.

Deciding When to Remove the Clutch

If you find any visible damage or wear and tear during your inspection, it’s time to remove the secondary clutch for a more thorough inspection or necessary repair.

Dismounting the Secondary Clutch

Got your tools ready? Let’s get to it.

Disconnecting the Clutch from the Drive Belt

Begin the process by removing the drive belt. Release the tension by pushing the secondary clutch towards the primary and loop the belt out from the sheaves.

Loosening the Holding Bolt

The secondary clutch is mounted on the jackshaft with a holding bolt. Use your wrench to loosen this bolt.

Using a Clutch Puller

Now you’ll need to use a clutch puller to disengage the secondary clutch from the jackshaft. Insert the puller into the centre hole of the hub and tighten it until the clutch breaks free.

Removing the Clutch

Once the clutch is free, you can slide it right off the jackshaft. Remember to be careful not to drop or damage the clutch during this process.

Handling Common Complications While Removing Secondary Clutch

Running into some obstacles? Don’t worry; we’ve got you covered.

Dealing with a Stuck Clutch

If the clutch is stuck, apply a penetrant spray, allow it to penetrate to the inner clutch assembly and try using the clutch puller again.

How to Overcome Tension in the Clutch Spring

To release the tension, you can use a clutch compressor tool. But remember, the springs hold a lot of energy, so use caution while handling to prevent personal injury or damage to the clutch.

What to Do When the Holding Bolt Won’t Budge

If the holding bolt is being stubborn, applying some heat with a blowtorch can help. But remember safety is paramount, so be extremely careful and protect the surrounding areas to prevent damage.

Cleaning the Removed Secondary Clutch

Four words: Do not skip this!

Importance of Cleaning the Clutch

A thorough cleaning will ensure the longevity and performance of the clutch by reducing friction, keeping the mechanism cool, and also revealing any hidden damage.

Choosing the Appropriate Cleaning Solvent

Pick a cleaning solvent specifically designed for clutch systems, which won’t leave any residue.

Steps to Clean the Clutch

Start by lightly brushing the clutch with a soft brush. Then, spray the solvent and use a dry cloth to wipe it clean. With a lint-free cloth, you can thoroughly dry the clutch before moving to the next step.

Dry Up and Lubrication After Cleaning

Give enough time for the solvent to evaporate completely. When it’s dried up, lightly lubricate the clutch using a high-quality lubricant to keep it functioning smoothly.

Evaluating Secondary Clutch after Removal

Now that you’ve removed and cleaned the secondary clutch, let’s give it another check-up.

Inspecting the Clutch for Damage

Take a closer look for any internal damage, cracks, or wear and tear that were not visible earlier.

Checking Clutch Bearings

The clutch bearings should be free from any dirt and rust. If they are not moving freely, it might be necessary to replace them.

When to Replace Your Secondary Clutch

If you find significant damage or if it’s been quite a while since the last replacement, consider replacing the clutch to maintain optimal performance.

Preparing for Secondary Clutch Reinstallation

Like any pro mechanic, make sure you’re fully prepared for the installation.

Cleaning the Clutch Housing

Clean the housing inside out to remove any dirt or debris before installing the clutch.

Collecting Required Tools

Get all your tools: a torque wrench, a new holding bolt if necessary, and a clutch alignment tool.

Checking the Clutch Alignment Tool

Quality tools are essential! Ensure that your clutch alignment tool is in good condition, as it’s crucial for getting the clutch aligned correctly.

Reinstallation of the Secondary Clutch

Ready to roll? Let’s get that clutch back in place.

Aligning the Clutch

Slide the secondary clutch onto the jackshaft, making sure that it aligns correctly with the alignment tool.

Tightening the Centrifugal Clutch

Tighten the new holding bolt using a torque wrench by following the recommended torque specification in the owner’s manual.

Reconnecting the Drive Belt

Finish the installation by reinstalling the drive belt onto the sheaves of the clutches.

Post Clutch Removal/ Installation Tips

Phew! That was quite a journey. Now, here are some closing thoughts.

Maintaining Your Clutch System

Regular maintenance is necessary for optimal performance. This includes cleaning, lubricating, and inspecting the primary and secondary clutches at regular intervals.

Common Signs of Clutch System Problems

If your snowmobile is feeling sluggish, if there’s excessive belt wear, or if it overheats easily, it could point to a problem within the clutching system.

When to Seek Professional Help

If you’re unsure or uncomfortable with any part of the process, seeking help from a professional mechanic is recommended. They can help guide you through the troubleshooting or repair process.

Congrats! You’ve successfully navigated your way through the secondary clutch on a Polaris snowmobile. Keep these points in mind, and you’ll have a more profound understanding of your snowmobile’s clutch system. And remember, proper maintenance is key to extended sledding seasons and countless snow-filled adventures!

- What Snowboard Bindings Should I Get? - January 23, 2024

- What Size Screws For Snowboard Bindings? - January 23, 2024

- How To Snowmobile On Water? - January 23, 2024